Inqubo Yokukhiqiza Ye-Vacuum Brazed Diamond Core Drill Bits

Inqubo yokukhiqiza izingcezu zokubhoboza amakhora edayimane eline-vacuum brazed ibandakanya uchungechunge oluyinkimbinkimbi lwezinyathelo zokuqinisekisa ukukhiqizwa kwethuluzi lokubhola lekhwalithi ephezulu, eliqinile. Lezi zingcezu zokubhoboza zibalulekile ezinhlobonhlobo zezicelo zezimboni, okuhlanganisa ezokwakha, izimayini, nokuthuthukiswa kwengqalasizinda. Inqubo iqala ngokuhlolwa kwezinto ngokucophelela nokulungiswa ukuze kuqinisekiswe ukugxila kanye nokunemba okuphelele kwe-matrix yensimbi. Lesi sihloko sihlinzeka ngemininingwane eningiliziwe yenqubo yokukhiqiza kusukela ekulungiseni izinto kuya ekufakweni kokugcina, okugqamisa ukunemba nobungcweti obudingekayo esigabeni ngasinye.

Ukuhlolwa Kwempahla Nokuzilungiselela

Isinyathelo sokuqala senqubo yokukhiqiza ibhithi ye-vacuum-brazed diamond drill ukuhlola ngokucophelela okokusebenza nokuqinisekisa ukugxila kwe-matrix yensimbi. Lokhu kuhilela ukuhlolwa kwekhwalithi okuqinile ukuze kuqinisekiswe ubuqotho nobukhulu be-substrate, kanye nokuhlanzeka nokoma kwempahla. Noma yikuphi ukuchezuka ezimfuneko ezishiwo kulungiswa ngokucophelela ukuze kugcinwe amazinga aphezulu okunemba. Uma impahla isidlulile ukuhlolwa, ihamba ngenqubo yokuhlanza ngokuphelele ukuze isuse noma yikuphi ukugqwala namafutha. Lokhu kufezwa ngokusebenzisa imishini ekhethekile ukuze kuqhunyiswe ngokulinganayo impahla, ukuyilungiselela ngokuphumelelayo izigaba ezilandelayo zenqubo yokukhiqiza.

Ukusetshenziswa Kweglue Ekhethekile Nokubekwa Kwezinhlayiya Zedayimane

Ngemuva kokulungiswa kwezinto ezibonakalayo, ingxenye eyinhloko yenqubo yokukhiqiza ukusetshenziswa kweglue ekhethekile ezingxenyeni zokusebenza zomkhiqizo. Inhloso yalesi sinyathelo ukukhuthaza ukunamathela kwezinhlayiya zedayimane ku-substrate, ukuqinisekisa isibopho esiqinile nesihlala isikhathi eside. Ukusetshenziswa kweglue ekhethekile kudinga ukunemba kanye nobuchwepheshe ukuze kuzuzwe ukumbozwa kulo lonke ungqimba olusebenzayo. Abasebenzi abanamakhono babe sebefafaza izinhlayiya zedayimane mathupha kungqimba olusebenzayo, baqinisekise ukusatshalaliswa okulinganayo kokusebenza kahle kokumba. Le nqubo yokucophelela ibalulekile ekufinyeleleni isibopho esikhethekile phakathi kwezinhlayiya zedayimane kanye ne-matrix, ukubeka isisekelo sokuqina okukhethekile kokubhola kanye nokusebenza kahle kokusika.

Izinqubo Ze-Brazing Nokucwengisiswa Kwentambo

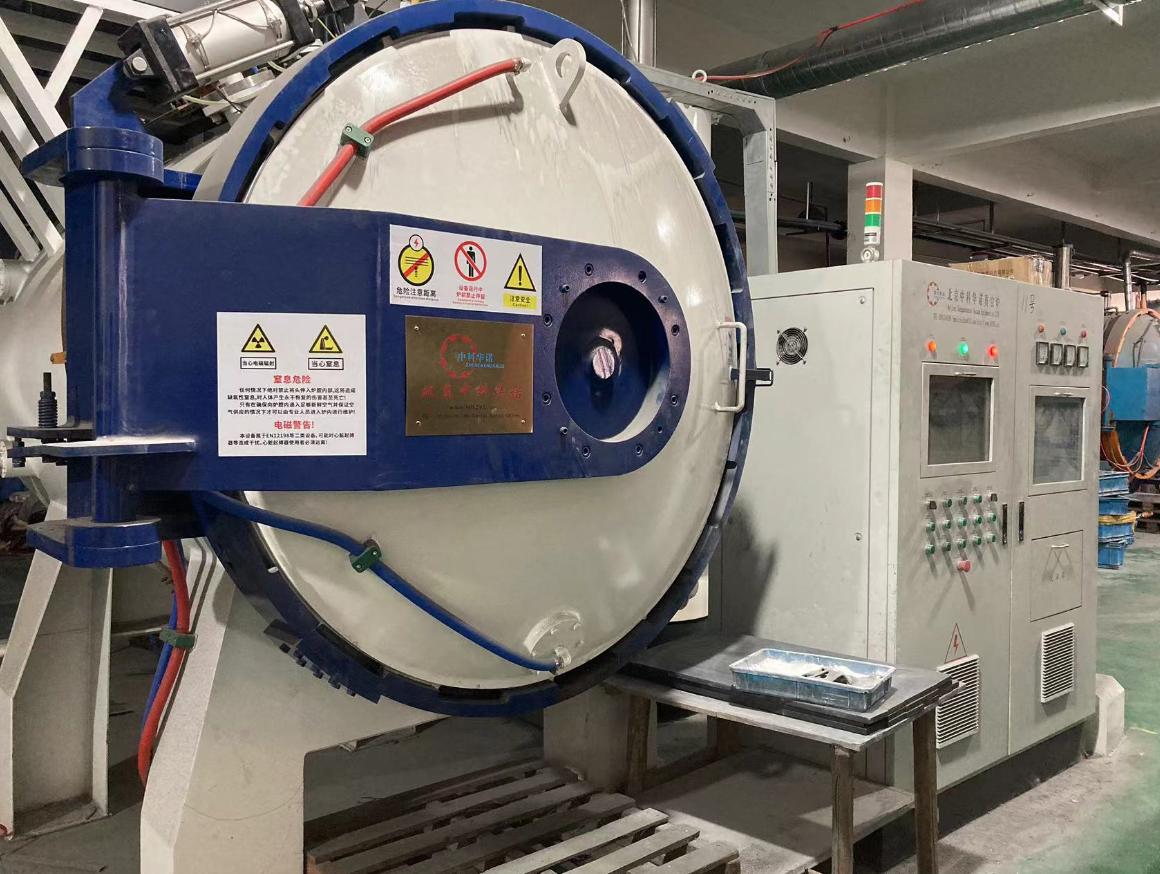

Uma izinhlayiya zedayimane sezisakazwa ngokulinganayo kungqimba olusebenzayo, i-drill bit ifakwa esithandweni somlilo ukuze kusetshenziswe inqubo yokubhula. Lesi sigaba esibucayi sibandakanya ukubeka i-drill bit emazingeni okushisa aphezulu ukuze ushumeke ngokuqinile izinhlayiya zedayimane ku-matrix. Inqubo yokubhula ilawulwa ngokucophelela ukuze kuqinisekiswe ukuhlangana okufanele kwezinhlayiya zedayimane kanye ne-matrix, okuholela kusibopho esiqinile nesithembekile. Ngemuva kwenqubo yokubhula, izintambo ze-drill bit zidinga ukuphinda zicushwe ukuze kuthuthukiswe ukugxila nokunemba kwezintambo. Lokhu kucolisiswa okucophelela kuqinisekisa ukuthi i-drill bit ihlangabezana nemininingwane eqondile edingekayo ekusebenzeni okunembayo, okusebenzayo kokumba.

Futha Ukupenda, Ukumakwa kweLaser, Ukwelapha Ukugqwala

Ngemuva kwezigaba zokucwenga nokucwenga intambo, i-drill bit ingena ezinqubweni zokuqedela ezengeziwe ukuze kuthuthukiswe ukusebenza kwayo nokuqina. Izisebenzi zasefekthri ezinekhono zipenda ngesandla ngokucophelela izingcezu zokubhoboza, zisebenzisa okokuvikela ukuze zivikele indawo engaphezulu futhi zithuthukise ubuhle bubonke. Ngemuva kokuthi upende lusetshenziswe, i-bit ivunyelwe ukuba yome kahle ukuze kuqinisekiswe ukuthi ihlala isikhathi eside futhi iphelile. I-drill ibe imakwa nge-laser ngolwazi olubalulekile, okuhlanganisa imininingwane yomkhiqizo nemininingwane yomkhiqizo. Le nqubo yokumaka enembayo yengeza isendlalelo sobuqiniso nokulandeleka kuma-drill bits, okuvumela ukuhlonza okulula nokuqinisekiswa kwekhwalithi. Ngemuva kokumaka i-laser, uwoyela we-anti-rust usetshenziswa endaweni ephawuliwe ukuze unikeze isendlalelo esengeziwe sokuvikela ekugqwaleni nokuqinisekisa impilo yesevisi ye-drill bit ezindaweni ezihlukahlukene zokusebenza.

Ukupakishwa kanye Nokuhlolwa Kwekhwalithi

Isigaba sokugcina senqubo yokukhiqiza sihlanganisa ukupakishwa ngokucophelela kwezingcezu zokubhoboza ngokwezidingo zamakhasimende. Lokhu kuhlanganisa ukunaka ngokucophelela imininingwane ekwakhiweni kokupakisha, ukulebula, nezinyathelo zokuvikela ukuze uqinisekise ukuthi umshini wokuvivinya ufinyelela ikhasimende usesimweni esingcono kakhulu ngangokunokwenzeka. Ukuhlolwa kwekhwalithi okuqinile kwenziwa kuyo yonke inqubo yokukhiqiza ukuze kutholwe noma yikuphi ukuchezuka noma amaphutha. Noma yimuphi umkhiqizo ongavumelani uzosetshenzwa kabusha noma isinyathelo sokulungisa ukuze kugcinwe izinga eliphezulu kakhulu kanye nezindinganiso zokunemba. Le ndlela ebanzi yokulawula ikhwalithi iqinisekisa ukuthi yonke insimbi yokubhoboza yedayimane ene-vacuum-brazed ephuma efekthri ihlangabezana nezidingo eziqinile zezinhlelo zokusebenza zezimboni, iletha ukusebenza okuthembekile nokuqina.

Ekuphetheni

Inqubo yokukhiqiza izingcezu zokumba amakhora edayimane evacuum iwubufakazi bobunjiniyela obunembayo kanye nobuciko bobuciko obucophelelayo. Kusukela ekuhlolweni kokuqala nasekulungiseni izinto kuya ekupakishweni kokugcina kanye nokuhlolwa kwekhwalithi, zonke izigaba zenqubo zibonakala ngokuzibophezela ekwenzeni okuhle kanye nekhwalithi. Inhlanganisela yobuchwepheshe obuthuthukisiwe, ubuciko obunamakhono kanye nezinyathelo eziqinile zokulawula ikhwalithi kuqinisekisa ukuthi izinsimbi zokubhoboza ezikhiqizwayo zihlangabezana nezidingo ezidingekayo zomsebenzi wokumba wezimboni. Ngokunamathela ezindinganisweni eziphakeme kakhulu zokukhiqiza, izingcezu zokumba amakhora edayimane evacuum brazed zihlala ziyithuluzi elibalulekile ekusetshenzisweni okuhlukahlukene, okunikela ekusebenzeni kahle nasekukhiqizeni ezimbonini ezahlukahlukene.