Inkqubo yokuVeliswa kweVacuum Brazed Diamond Core Drill Bits

Inkqubo yokwenziwa kwe-vacuum-brazed diamond drill drill bits ibandakanya uchungechunge olunzima lwamanyathelo okuqinisekisa ukuveliswa kwesixhobo sokubhola esikumgangatho ophezulu, esomeleleyo. Ezi zixhobo zokuqhuba zibalulekile kwiinkqubo ezahlukeneyo zemizi-mveliso, kubandakanywa ulwakhiwo, imigodi, kunye nophuhliso lweziseko ezingundoqo. Inkqubo iqala ngokuhlolwa kwezinto ngokucokisekileyo kunye nokulungiswa kokuqinisekisa ukugxila kunye nokuchaneka okupheleleyo kwe-matrix yentsimbi. Eli nqaku linika inkcazo ecacileyo yenkqubo yokuvelisa ukusuka kumalungiselelo ezinto eziphathekayo ukuya kwipakethe yokugqibela, igxininisa ukuchaneka kunye nobuchule obufunekayo kwinqanaba ngalinye.

Ukuhlolwa kwezinto eziphathekayo kunye noLungiselelo

Inyathelo lokuqala kwinkqubo yokwenziwa kwebit engundoqo yedayimane evacuum-brazed kukuhlola ngononophelo imathiriyeli kunye nokuqinisekisa ubunzulu bematrix yentsimbi. Oku kubandakanya ukuhlolwa komgangatho ongqongqo ukuqinisekisa ukuthembeka kunye nemilinganiselo ye-substrate, kunye nokucoceka kunye nokoma kwezinto eziphathekayo. Nakuphi na ukutenxa kwiimfuno ezichaziweyo kuqwalaselwa ngononophelo ukuze kugcinwe eyona migangatho iphezulu yokuchaneka. Emva kokuba izinto zigqithise ukuhlolwa, zihamba ngenkqubo yokucoca ngokucokisekileyo ukususa nayiphi na i-rust kunye ne-oil stains. Oku kufezekiswa ngokusebenzisa oomatshini abakhethekileyo ukuze baqhume ngokulinganayo izinto eziphathekayo, zilungiselele ngokufanelekileyo kwizigaba ezilandelayo zenkqubo yokuvelisa.

Ukusetyenziswa kweGlue eKhethekileyo kunye nokuBekwa kweeNcam zeDayimane

Emva kokulungiswa kwezinto, inxalenye ephambili yenkqubo yokuvelisa kukusetyenziswa kweglue ekhethekileyo kwiindawo zokusebenza zemveliso. Injongo yale nyathelo kukukhuthaza ukunamathela kwiincinci zedayimane kwi-substrate, ukuqinisekisa ukuba ibhondi eyomeleleyo kunye nexesha elide. Ukusetyenziswa kweglue ekhethekileyo kufuna ukuchaneka kunye nobuchule ukuze kuphunyezwe nokuba kugutyungelwe kulo lonke uluhlu olusebenzayo. Abasebenzi abanezakhono emva koko bafefa ngesandla amasuntswana edayimani kumaleko okusebenza, beqinisekisa ukusasazwa okulinganayo ukuze kusetyenzwe kakuhle. Le nkqubo yobuchule ibalulekile ekufezekiseni iqhina elikhethekileyo phakathi kwamasuntswana edayimani kunye ne-matrix, ibeka isiseko sokuqina okugqwesileyo kwe-drill kunye nokusebenza kakuhle kokusika.

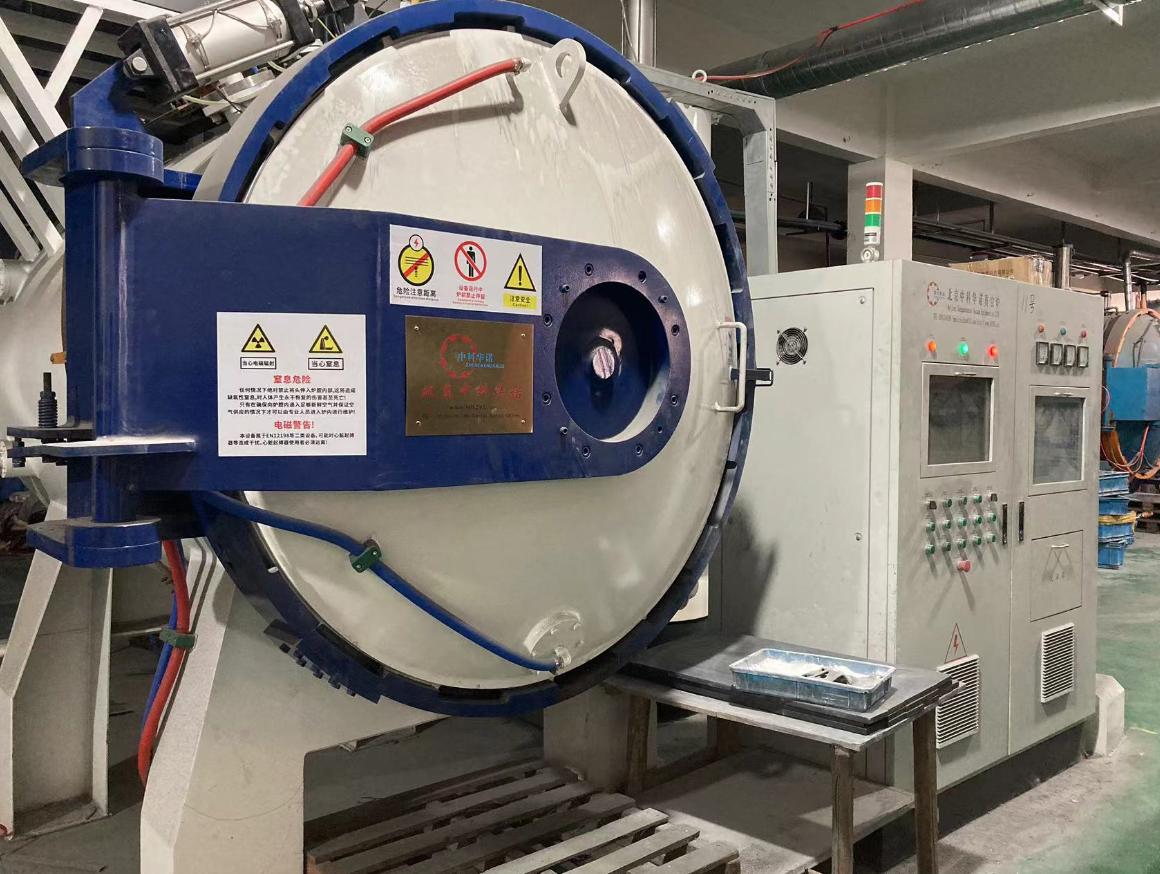

Iinkqubo zeBrazing kunye nokucokisa imisonto

Emva kokuba i-diamond particles ihanjiswe ngokulinganayo kwinqanaba lokusebenza, i-drill bit ifakwe kwisithando somlilo kwi-brazing process. Eli nqanaba libaluleke kakhulu libandakanya ukuthobela i-drill bit kumaqondo obushushu aphezulu ukubethelela ngokuqinileyo amasuntswana edayimani kwi-matrix. Inkqubo yokuqhafaza ilawulwa ngokucophelela ukuze kuqinisekiswe ukuxhamla ngokufanelekileyo kweengqungquthela zedayimane kunye ne-matrix, okubangelwa ukudibanisa okuqinileyo nokuthembekileyo. Emva kwenkqubo yokuqhafaza, iintambo ze-drill bits zifuna ukuphinda zihlanjwe ukuze kuphuculwe ukugxila kunye nokuchaneka kweentambo. Olu lungiso lucokisekileyo luqinisekisa ukuba i-drill bit ihlangabezana nemigaqo echanekileyo efunekayo kwimisebenzi echanekileyo, esebenzayo yokomba.

Ukupeyintwa kokutshiza, ukuphawulwa kweLaser, unyango lokulwa nokurusa

Emva kwezigaba zokucoca kunye nentambo, i-drill bit ingena kwiinkqubo ezongezelelweyo zokugqiba ukunyusa ukusebenza kwayo kunye nokuqina. Abasebenzi befektri abanobuchule bapeyinta ngokucokisekileyo i-drill bits, besebenzisa i-coating yokukhusela ukukhusela umphezulu kunye nokuphucula ubuhle jikelele. Emva kokuba ipeyinti isetyenzisiwe, i-bit ivunyelwe ukuba yome ngokucokisekileyo ukuze kuqinisekiswe ixesha elide kunye nokugqiba. I-drill ke laser-iphawulwe ngolwazi olubalulekileyo, kuquka iinkcukacha zemveliso kunye neenkcukacha brand. Le nkqubo yokumakisha ichanekile yongeza umaleko wobunyani kunye nokulandeleka kwimingxuma yokomba, ivumela ukuchongwa lula kunye nokuqinisekiswa komgangatho. Emva kokumakishwa kwe-laser, ioli echasene ne-rust isetyenziswe kwindawo ephawulweyo ukuze inikeze umaleko owongezelelweyo wokukhusela kwi-corrosion kunye nokuqinisekisa ubomi benkonzo ye-drill bit kwiindawo ezahlukeneyo zokusebenza.

Ukupakishwa kunye noHlolo loMgangatho

Inqanaba lokugqibela lenkqubo yokuvelisa libandakanya ukupakishwa ngokucophelela kwee-drill bits ngokweemfuno zabathengi. Oku kubandakanya uqwalaselo olucokisekileyo kwiinkcukacha kuyilo lokupakisha, ukuleyibhela, kunye namanyathelo okukhusela ukuqinisekisa ukuba i-drill ifikelela kumthengi ngeyona meko ingcono kakhulu. Ukuhlolwa komgangatho ongqongqo kuyenziwa kuyo yonke inkqubo yemveliso ukubona nakuphi na ukutenxa okanye iziphene. Nayiphi na imveliso engahambelaniyo iya kuphinda isetyenziselwe okanye ithathelwe amanyathelo olungiso ukuze kugcinwe owona mgangatho uphezulu kunye nemigangatho yokuchaneka. Le ndlela ibanzi yolawulo lomgangatho iqinisekisa ukuba yonke intwana yedayimani efunxayo yebrazed ephuma kumzi-mveliso ihlangabezana neemfuno ezingqongqo zezicelo zemizi-mveliso, inikezela ukusebenza okuthembekileyo kunye nokuqina.

Ukuququmbela

Inkqubo yokwenziwa kwemingxuma yokomba yedayimane efunxayo ibrazed bubungqina bobunjineli obuchanekileyo kunye nobuchule bobugcisa obunobuchule. Ukusuka ekuhlolweni kokuqala kunye nokulungiswa kwemathiriyeli ukuya ekupakishweni kokugqibela kunye nokuhlolwa komgangatho, inqanaba ngalinye lenkqubo liphawulwa ngokuzinikela ekugqweseni kunye nomgangatho. Indibaniselwano yobuchwephesha obuphezulu, ubugcisa bezakhono kunye nemilinganiselo yolawulo engqongqo yobulunga iqinisekisa ukuba amasuntswana okomba avelisiweyo ahlangabezana neemfuno ezibango zemisebenzi yokugrumba kwimizi-mveliso. Ngokubambelela kweyona migangatho iphezulu yemveliso, i-vacuum brazed diamond drill drill bits zihlala zisisixhobo esiyimfuneko kwizicelo ezahlukeneyo, ezinegalelo ekusebenzeni kakuhle kunye nemveliso kumashishini ahlukeneyo.